Understanding Circuit Basics

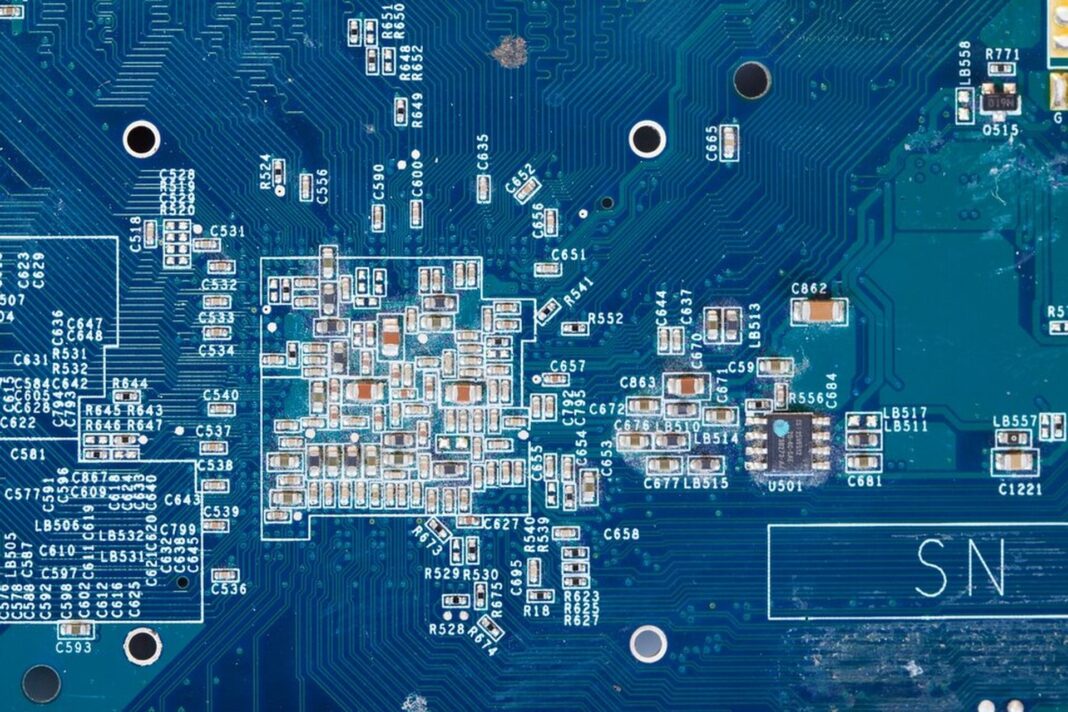

Electronic systems start with circuits. Each circuit component has a distinct function. Resistors, capacitors , diodes , transistors and integrated circuits make up a circuit. Electronics workers must understand how these components interact. Key concepts are voltage current and resistance. Ohm Law links them. Circuit problems may be diagnosed by measuring these values.

A battery and light bulb form a circuit. Electricity illuminates the lamp. Complex circuits feature interconnected components. To master electronics you must understand how they work. Parallel and series circuits react differently. Parallel circuits contain many current routes whereas series circuits have one. This impacts component voltage and current sharing.

Understanding these principles enhances electronic enjoyment. It equips anybody for challenging tasks. Theory and practice go together. Test circuit kits to get confidence. As abilities increase, unique circuit design will evolve. Learning circuit fundamentals provides us with many technological options.

Identifying Common Errors

Circuit fault detection saves time and stress. Beginners often confront project obstacles. Misplaced components and inadequate connections are common mistakes. Diodes and capacitors need polarity checks. A reversed connection may kill a circuit.

Common mistakes include loose connections. Lightly linked wires lack a robust electrical connection. This causes sporadic connectivity and irregular performance. A multimeter can trace connections and discover issues. Circuit continuity testing ensures all parts are connected.

Review component values too. An improper resistor might break the circuit. Check label specs against circuit design. Checking power supply voltage helps avoid problems early. Undervoltage may prohibit the activity while overvoltage damages components.

Troubleshooting requires documentation. Detailed circuit design and modification logs assist with repairs. By studying typical faults circuit assembly may be improved. Systematic inspections improve dependability. This discipline improves workplace efficiency.

Common Soldering Mistakes

Soldering is essential in electronics yet errors are common. Beginners may overheat destroying components. Proper tip temperature improves solder flow without damaging the circuit. Maintaining 350 degrees Celsius is essential.

Insufficient solder is another common mistake. Undersoldering weakens joints causing connections to break. The soldered junction should shine and be smooth. Overheating causes cold solder junctions therefore preventing it. Though attractive these joints work poorly owing to weak electrical contact.

Placement matters in soldering. Design components should align. Misalignment may cause short circuits complicating repairs. Helping hand tools secure components when soldering. This reduces errors.

Improving electrical connections requires solder flux. Too much flux might cause problems. Soldering requires flux cleanup. Prevents corrosion and cleans circuit surfaces.

Soldering with different components improves skills. Comfort boosts job quality. Errors strengthen knowledge. Soldering confidence boosts electrical project success.

Troubleshooting Techniques

Troubleshooting is crucial in electronics. It diagnoses circuit problems. A systematic approach streamlines the work. Visualize the circuit and its function. Knowing its intended purpose reveals possible issues.

Troubleshooting using a multimeter is helpful. This device monitors voltage current and resistance. Checking these numbers at certain moments identifies issues. Check the power supply. Lack of electricity might cause an unresponsive circuit.

Next inspect each part. Testing resistors, capacitors and other elements assures operation. Check for burns or cracks. Check the circuit for loose connections and shorts. Careful study typically exposes hidden concerns.

Troubleshooting notes generate a log for further reference. Record findings and actions. Practice creates a personal troubleshooting guide. Group conversations or forums may illuminate problems. Knowledge sharing improves problem solving.

Troubleshooting requires persistence. Time may be needed to resolve complex circuits. Learning to troubleshoot allows one to handle complex technological tasks. It turns failures into learning opportunities advancing electronics.

How To Read A Circuit Diagram

Circuit diagram reading is vital for electronics hobbyists. Diagrams clarify difficult concepts graphically. Standardized symbols help explain component functionality. Diagram symbols include resistors, capacitors and diodes.

Reading a circuit diagram starts with symbols. Interpretation requires familiarity with these visual signals. Once symbols are known component relationships may be analyzed. Lines show circuit wiring and relationships. Series and parallel connections demonstrate circuit component interactions. Parallel connections have many electrical paths whereas series connections have one.

Understanding is easier by seeing electricity. Following each connection from the power source shows how electricity flows across the circuit. Understanding component functions improves circuit understanding. Simple diagrams with fewer parts are good beginning points. More complex circuits become doable as abilities improve.

Practical experience improves circuit diagram reading. Building circuits from pictures improves comprehension. This hands-on method applies theory. Learning to understand circuit diagrams boosts circuit design and troubleshooting confidence.

Overcoming Component Misplacement

Projects might fail due to component misplacement. Correct component placement is crucial for circuit operation. This is difficult for beginners. Overlooking component orientation is typical. Polarized components include diodes and electrolytic capacitors. Failure to position them appropriately might cause circuit failure.

Labels help with misplacement. Clear markings assist in monitoring component location during construction. A comprehensive circuit diagram inspection before beginning provides a solid foundation. Stepping through the circuit mentally helps visualize the result. Documenting assembly steps simplifies troubleshooting.

Multiple placement checks may avoid major mistakes. Verifying component location and orientation saves time and work later. Get a second viewpoint from another enthusiast for crucial insights. Another viewpoint might reveal missing locations.

Practice improves component placement accuracy. Simple tasks build skills for sophisticated assembly. Each activity improves comprehension. Overcoming component misplacement becomes second nature to electronics construction with experience.

What Are The Most Common Circuitry Mistakes?

Circuitry faults are prevalent among beginners and experts. These mistakes commonly result from misreading circuit schematics or simple principles. Component placement errors like resistors and capacitors are common. This causes circuit failures.

Using incorrect component values is another common mistake. An incorrectly rated resistor might change behavior. Diodes might malfunction if their polarity is not checked. A minor error may break a circuit.

Poor soldering skills cause mistakes. Cold solder junctions and extra solder may create intermittent connections and unpredictable behavior. Loose cables and connections may potentially disrupt current flow. Avoiding these issues requires regular monitoring.

Keeping thorough error logs improves procedures. Understanding what went wrong helps improve future efforts. Learning from mistakes helps you improve.

How Can I Improve My Soldering Skills?

Improved soldering skills boost electronics expertise. The best way is to practice. Working on projects regularly improves skills. Each finished solder junction improves skill and comfort.

Tool knowledge is crucial. Soldering iron solder and assisting hands should be body extensions. Quality tools provide better outcomes than cheap ones. Maintenance improves soldering iron efficiency.

Soldering procedures must be understood. Too much heat may harm components therefore temperature regulation is crucial. Maintain balance to ensure material flow without overheating. The solder should be used to make strong connections.

A soldering lesson or online course might be helpful. Discovering improving recommendations from others‘ experiences is common. Community workshops and forums provide input.

Soldering requires patience. Over time the effort will boost confidence and job quality. Soldering is crucial in electronics since it improves abilities to handle complicated circuits.