IoT integration in manufacturing and supply chain activities has changed industries. This technology links machines, devices and systems for efficiency and transparency. IoT systems monitor and analyze data in real time helping organizations make choices. Business processes may be greatly improved by using IoT. The following sections discuss IoT in manufacturing and supply chain management.

How Iot Enhances Supply Chain Visibility

IoT greatly improves supply chain visibility. It lets organizations monitor shipments and inventories live. GPS and sensors offer precise position data. Visibility improves decision making. Delays and inventory shortages may be addressed promptly by businesses. Better tracking lowers lost items. For supply chain transparency stakeholders may access data anytime.

IoT technologies provide firms with operational information. They may anticipate problems via data analysis. This foresight aids resource planning and management. Automated notifications may warn management of irregularities. Quick reactions reduce downtime and streamline operations.

Visibility boosts customer service. Customers anticipate order updates in real time. IoT lets firms predict delivery times accurately. Customers are more loyal when satisfied. Companies that invest in IoT may gain a competitive advantage.

Predictive Maintenance: A Game Changer For Manufacturers

Manufacturing is being transformed by predictive maintenance. IoT monitors machinery health continually. Monitoring helps prevent failures. Manufacturers may plan maintenance. This method greatly decreases unnecessary downtime. Equipment efficiency boosts production.

By examining machine data firms may spot performance patterns. Knowing when equipment may fail improves maintenance planning. It reduces production disturbances. Thus firms save on upkeep.

Predictive maintenance reduces reactive repair costs. Resource allocation becomes more efficient improving operations. Real time data analysis from IoT solutions detects part wear. More responsive operators lengthen equipment lifespans and improve operational dependability.

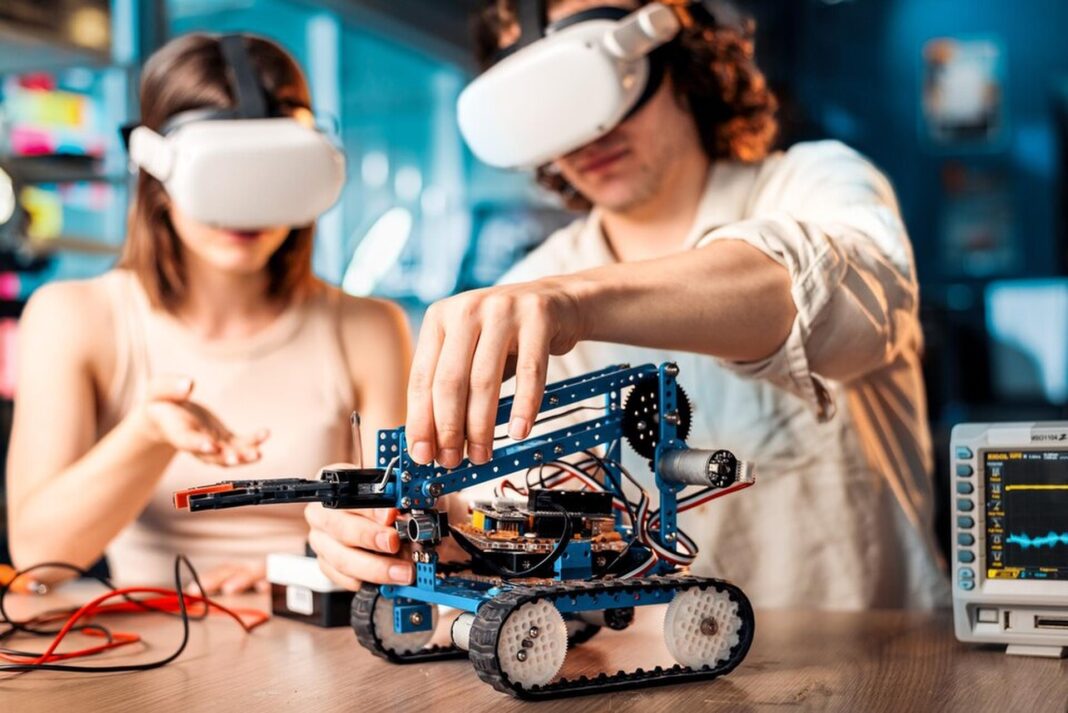

Staff must be trained in predictive maintenance. Experts may use data analytics. Proper training fosters proactive managerial care. These improved processes provide manufacturers with a competitive edge. Predictive maintenance cuts costs and improves quality.

The Impact Of IoT On Production Efficiency

IoT has several effects on manufacturing efficiency. It streamlines operations by connecting equipment systems and personnel. Live data collecting improves productivity and eliminates delays. Connected gadgets reduce production bottlenecks.

Manufacturing is more consistent and accurate with automation. IoT machines may alter operations depending on real time input. This adaption improves product quality and reduces waste. Firms can better match market demand.

Data analytics helps manufacturers improve operations. IoT insights allow ongoing improvement. Businesses can quickly see problems. They may adjust operations based on data.

IoT solutions boost manufacturing production. Efficiency boosts ROI quickly. Less repetitious work benefits employees. Focus on higher value activities boost innovation and development. IoT enabled businesses will thrive in the ever changing market.

Real Time Data Analytics In Manufacturing

Real time data analytics is changing manufacturing. IoT devices regularly capture massive amounts of data. Instant information leads to educated decision making. Real time data analysis boosts efficiency.

Manufacturers can monitor manufacturing live. They spot inefficiencies and bottlenecks. Workflows may be optimized quickly. Companies may simplify operations with real time visibility.

Data analytics reduces costs too. Insights from data analysis help management decrease costs. Understanding resource allocation improves financial planning. IoT powered data analytics investments pay off.

Data analytics also encourages teamwork. Departments discuss ideas promptly. Effective communication cuts down organizational silos. Teams achieve operational success by working collaboratively.

Manufacturers must maximize real time data analytics. People who use this technology can compete in a changing market. Provides manufacturing trend analytics for foresight and agility.

Ensuring Quality Control With IoT Solutions

Manufacturing quality control relies on IoT technologies. Improved data monitoring and analysis aid quality assurance. IoT devices track product quality throughout manufacture. Auto inspections prevent mistakes and ensure standards.

These sophisticated systems improve consistency. IoT sensors measure temperature and humidity. Continuous monitoring optimizes product manufacture. The immediate feedback enables swift modifications if criteria are not reached.

The use of IoT in quality control reduces waste. Early fault diagnosis reduces product rejection. Significant cost savings result from this decrease. Companies can make better consumer products.

Training staff to use IoT technologies is essential. Professionals may use technology to improve quality. Progress is encouraged by regular evaluations. Businesses must emphasize quality control to compete.

Technology driven quality control helps manufacturing succeed. IoT solutions fulfill high customer criteria. Companies may improve customer happiness by producing great goods.

IoT Enabled Workforce Automation

IoT enabled workforce automation is changing industries. Companies may simplify processes by linking equipment and machines. Automation lets workers concentrate on more important tasks. Machines may do repetitive or manual jobs improving efficiency.

IoT enables real time team collaboration. Workers can easily access many data sources. Improved cooperation creates a cohesive workplace. Employees adapt well to shifting demands.

Automation improves operational precision. Machines reduce mistakes by doing precise jobs. Improved uniformity boosts product quality. This stability reduces production concerns and boosts customer satisfaction.

Automating the workforce using IoT cuts expenses. Companies save a lot on labor and management. Businesses may expand smoothly by automating procedures.

Workforce training and reskilling are crucial. Workers must be able to use automated systems. Focusing on flexibility prepares workers for the manufacturing future. Companies that automate their workforces using IoT gain an advantage.

What Are The Benefits Of Using Iot For Predictive Maintenance?

Using IoT for predictive maintenance has several benefits. Businesses may continually check equipment conditions. Continuous observation identifies concerns before they worsen. Efficiency in maintenance scheduling reduces unplanned downtime. Companies save money and resources with fewer unscheduled maintenance.

Predictive maintenance extends machinery life. Preventive maintenance keeps equipment dependable. Companies can boost productivity and performance. Data insights from IoT devices improve decision making. Data driven management helps managers allocate resources.

Safety is another advantage. Identifying hazards with predictive maintenance reduces worker danger. Proper equipment maintenance saves expensive failures. IoT integration promotes efficiency and productivity in enterprises.

How Can Iot Transform Supply Chain Management?

IoT might change supply chain management. One of the biggest advantages is increased visibility. Companies may monitor inventories and shipments live. This enables precision decision making enhancing operations.

Data from IoT devices helps estimate demand. Trend analysis improves planning and resource allocation. Businesses may cut inventory and expenditures.

Additionally automation boosts efficiency. Automation handles supply chain tasks. Simplifying workflow improves reaction times and customer service.

Another transformational factor is stakeholder cooperation. Suppliers and partners communicate better to keep informed. Information flows more freely improving the supply chain ecology.

Supply chain management using IoT may enhance agility, cost savings and flexibility. Companies may stay competitive in a changing market by modifying their tactics. The advantages are evident ushering in a new supply chain era.